Forklifts and other material handling equipment were made to make transporting heavy goods and easily maneuver these loads within the space area of the company or store. However, the usage of this heavy duty equipment also comes with a series of risks if used incorrectly. As reported by OSHA (Occupational Safety and Health Administration), an approximate of 11% forklift-related accidents happen every year. This is why it is important for forklift operators and operations managers to be guided through a comprehensive and proper training program.

But to give you a head’s start on familiarizing yourself in using these forklift machines, we made a rundown of the basic things you need to know when it comes to forklift maintenance to increase the safety of your workplace and your employees.

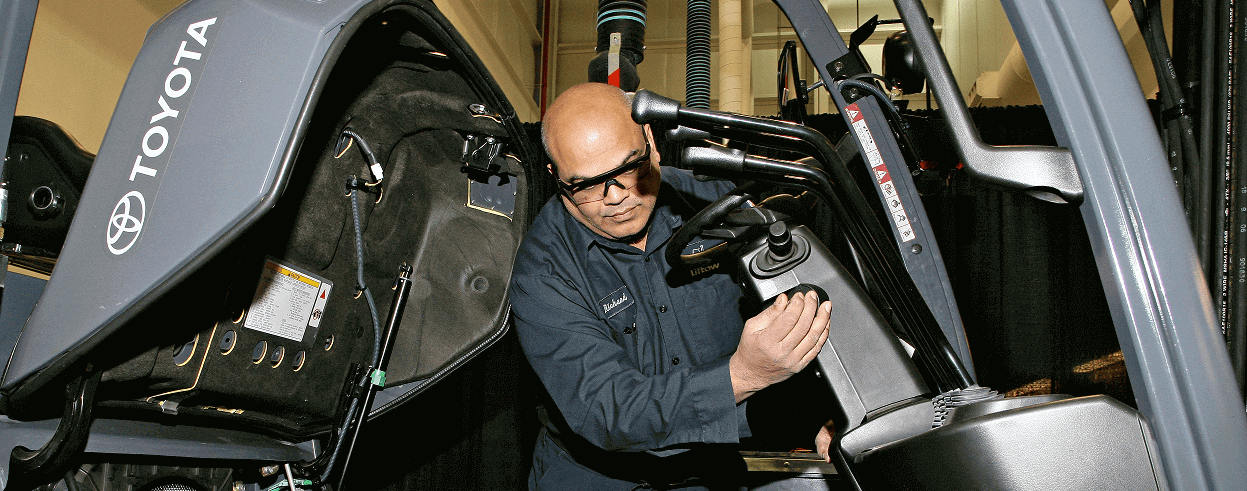

Prepare a pre-operation checklist

Before you put your forklifts into motion and perform the daily tasks ahead, it should at least be thoroughly inspected. Create a pre-operation checklist where you can take note of your forklifts current working condition and if the machines underwent maintenance/repair recently. From top to bottom, each part of it has the risk of malfunctioning if left unchecked. Make sure that you check each crook and cranny of the forklift, especially the breaks since it largely contributes to a series of accidents.

Determine safe travel routes

Forklift operators are required to check their travel routes so they can determine if there are hazardous areas that need to be cleared first. Through this habit you can lessen the risks and also improve the work flow.

Do not go over your forklift’s load capacity

To avoid heavy loads from tipping and falling on your employees and other goods when being moved, make sure that the weight and size of the load you will be carrying (via forklift) is not over the maximum capacity. Look at it this way, when you observe the load capacity, it actually helps you speed up your daily tasks and avoid the habit of putting on too much load that you risk placing unnecessary strain to your fork which may endanger your workmates sooner or later.

Drive responsibly

Once you are done with your pre-operations checklist, you can move on to operating your forklift. Here are some important reminders for you when driving the forklift:

- Do not drive when the fork is up and ensure your load is being carried at a low level

- Reduce your speed when turning, approaching intersections, and if there are incoming traffic

- Wear your seatbelts at all times and move at an appropriate speed if the road is wet and slippery

- Give yourself enough space when stopping the vehicle, which means hitting the breaks once you

- have reached a certain distance before you go to a complete stop

Regular training programs are a must!

Last but not least, do not skimp on the training. Training programs such as the OSHA-30 are regularly updated, so it is essential to attend such training programs to ensure you stay OSHA compliant each year. OSHA also requires employers to develop and implement a forklift operator training program for its employees. This means that managers must provide an intensive training for its forklift operators to have ample knowledge of safety operations & procedures. Considering this is a high-risk job, training programs should be included in their KPIs so that the trade rules and tricks are fresh in one’s mind.