Timber flooring is a trendy option, adding beauty to any space, be it your bedroom, living room or the kitchen. Maintain the right ambiance, showcase décor pieces, and the entire area would look so serene, especially if soft rays of the sun fall down onto the laminated timber flooring.

But as beautiful as reclaimed timber flooring may be, they also require sealing and other protective coatings so that they aren’t damaged by dust and other environmental factors. And this is not just limited to indoor furniture…

These days many people love having a wooden bench on the porch. I have one and it is my favourite coffee-sipping seat!!! It is strongly built and comfortable as well. However, after the rainstorms, the finish started to peel and the wood started to warp and that’s when I realized that it wasn’t built for outdoors. But a proper finish can come to your rescue. Though it won’t help it to sustain lifetime, but it will definitely help your piece survive longer in the outdoors. So let’s review some of the most suitable finishes for recycled timber flooring:-

Timber flooring finishing options fall under four broad categories: alkyds and curing oils, waxes and penetrating oils, polyurethanes and oil modified urethanes. Except for waxes and penetrating oils, the remaining types are available in both waterborne and solvent borne forms. Polyurethane finishes are also available in aromatic or yellowing and aliphatic or non yellowing types.

Volatile organic (solvent) content (VOC) ranges from low to high for all four categories. Glossiness varies from matte to very high gloss. Performance parameters like durability are different for each finishing category. Additional options like refurbishment coats are also available.

Penetrating Oils

These types of outdoor finishes for laminated timber flooring are a blend of waxes and oils to which chemical salt driers may be added. These substances are dissolved into low volatile spirit solvents. Waxes and penetrating oils require frequent maintenance, which involves applying acrylic polishes.

But then, this finishing option maintains timber’s natural appearance, and is often preferred. However, if the coating becomes old, the colour may darken.

Waxes

Wax increases the life of timber floors, and should definitely be used regularly so as to improve the shine. However, wax can build up which must be avoided by rubbing the surface with a neutral detergent.

Wax can also be applied on unsealed timber floor, particularly if they are solvent based. Rub them well into the grain and buff well with a polisher. When the first coat is applied, white sprit should be mixed in small quantities. This allows wax to enter the pores, hardening the surface for greater durability.

If the recycled timber flooring already has been subjected to water based salt, then only water based wax should be used.

Alkyds and Curing Oils

The best oil based finishes are curing oils like linseed and Tung, which are mixed with white spirit or mineral turpentine. Chemical agents, referred to as metal driers, may be added. Oil based finishing options are of good quality, produce a rich colour and are affordable. With age, they may also darken.

Compared to other finishing options, the durability of oil based finishes is on the lower side. But the edge bonding resistance is quite good. Curing oil finishes are available in a variety of gloss levels including high gloss and satin.

Alkyds are made by reacting curing oils and synthetic resin and then dissolving the compound into a spirit solvent. The durability of the resultant finish improves, which somewhat reduces maintenance needs, but it’s still there. Still the option is economical so alkyds are often used as finishes for timber flooring.

Oil Modified Urethanes or UMOs

These coatings feature a mixture of urethane and oil. If urethane proportion is higher, then the finishing substance is more flexible and offers better resistance to edge bonding. Oil modified urethanes are available in several gloss options.

Waterborne UMOs are also used, even though they are priced higher than solvent borne finishes; their advantage is low VOC emissions.

Both solvent borne and waterborne finishes yellow with age. In cold weather, curing is slow. Still they are preferable because they lie in an immediate range and not priced too high. Performance is also acceptable.

Solvent Borne Polyurethanes

Solvent borne polyurethane is one of the most common and durable of all the outdoor finishing options for timber flooring. The offered gloss options are the highest. On the low side, a strong solvent smell is emitted when they are being applied. Toxicity is also high until the coating cures, especially if the finishing is of the 2 pack kind. If protective equipment is used properly, toxicity or odour isn’t a concern.

Polyurethane may or may not yellow depending upon its kinds. This finishing option requires low maintenance because they offer the highest resistance and the maximum durability, but edge bonding resistance is poor. Prices lie in an intermediate range.

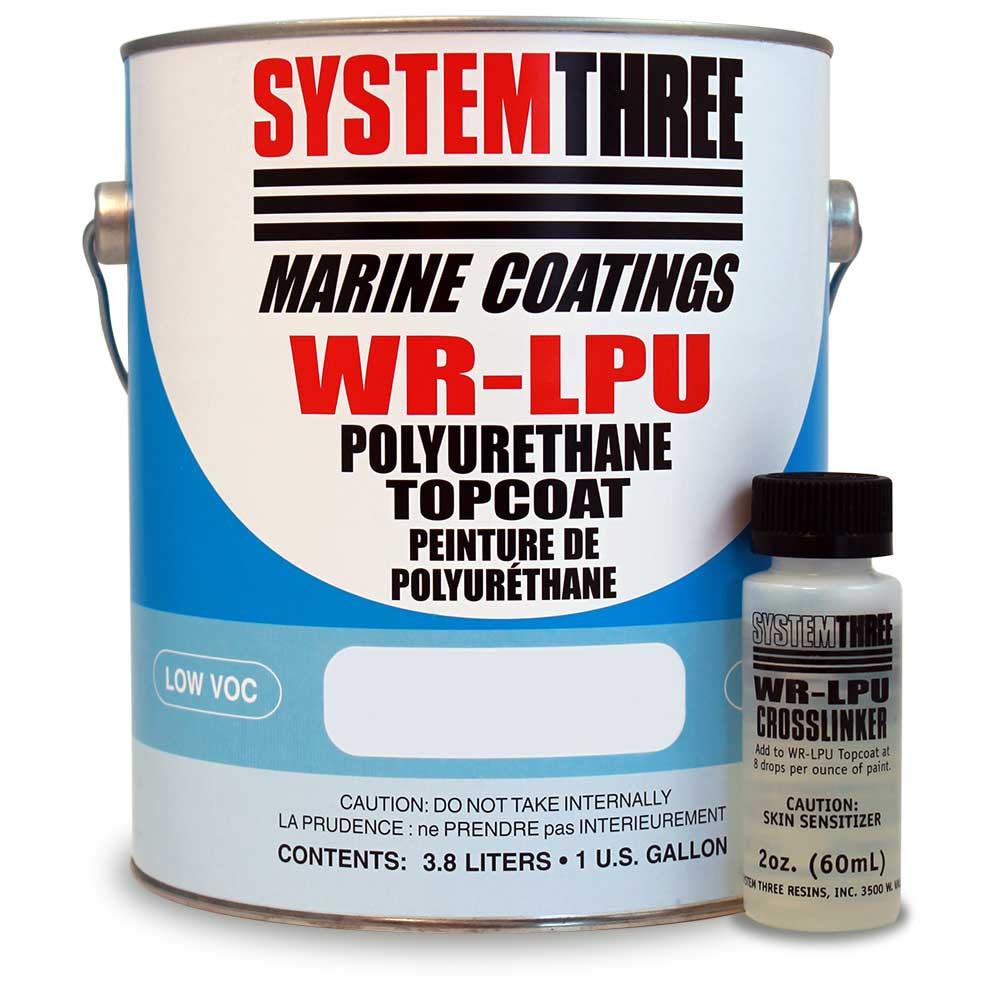

Waterborne Polyurethane

Water borne polyurethane can be further divided into many other kinds such as copolymer urethane acrylates, polyurethane resins and several blends. They are available with and without silicone and wax additives. Properties vary widely depending on the chosen type. Finishes without acrylic offer a better resistance to wear. Gloss options range from matte to high gloss. Though these finishes do darken, it’s not as significant as with other types. Edge bonding resistance is good.

Care must be exhibited when selecting a suitable finish. Both one pack and two pack options are available. Two pack finishes may use a low toxicity hardener or a more toxic crosslinker. Waterborne polyurethanes are the most expensive option.

Button Polishes

Button polish comprises of shellac resin, which has been melted into tiny flakes, resembling buttons. Alcohol or methylated spirits are often mixed to improve properties.

Button polish must be applied into two steps. The coats applied first must be thick and rubbed thoroughly on the grain. The second layer must be thin and should be applied only after the initial coat has dried out properly. Upon applying the second coat, the polish sinks well into the timber, hardening the surface and making it water resistant.

Stains

Stains can be used for any kind of timber flooring. Water based stains offer a more natural and even look. Before applying the finishing on the entire surface, test only a corner. Sealing must be compatible with the stain used. So wait sometime before the stain is applied all over the timber floor.

Stay tuned to our blog for more advice on timber properties, usage, applications and products!

About Author:-

Simon is an entrepreneur and self proclaimed jack of all trades. Simon has experience in the building and home renovation industry and he knows what it takes to knock out a successful project. CCurrently, he works with Smarter Timber Flooring, one of the prominent timber flooring suppliers in Melbourne. A big kid at heart if it goes fast, bounces, slides or you can climb it Simon has put it to the test.