If you go online and read up on fiberglass conduits and other products, you may find lots of articles and blog posts that seem to use the terms “fiberglass” and “fiber-reinforced plastic (FRP)” interchangeably. They may mention using special engineered fiberglass composites and just call them their own version of fiberglass or FRP.

One school of thought does maintain that there’s no difference between the two. Proponents of this opinion contend that FRP is simply another way for some manufacturers to imply a “better” or “more advanced” version of fiberglass. But they say that FRP and fiberglass is one and the same.

However, from a technical standpoint this isn’t quite accurate.

What’s Fiberglass?

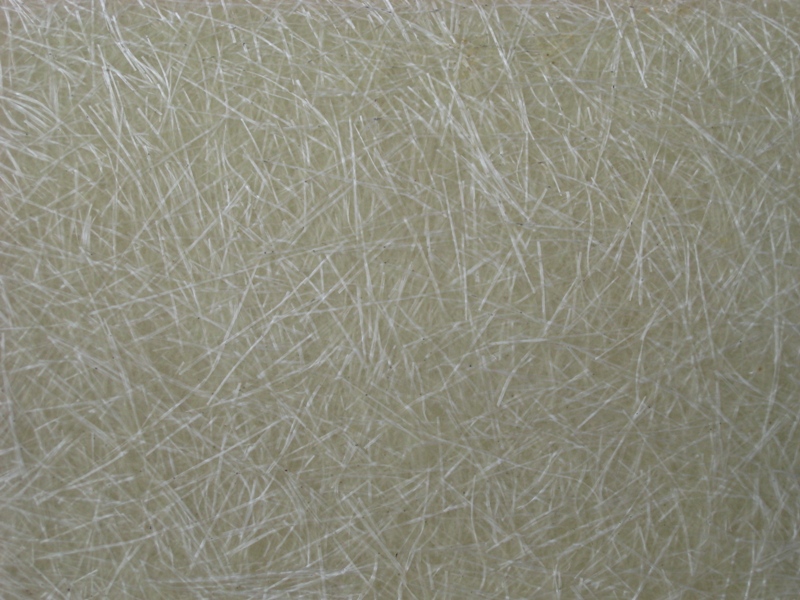

Technically, you get fiberglass when you melt spinning glass to get fibers of the glass. This can be in itself a final product which can be used for insulation, though the use of glass makes it brittle.

But the fibers can also be used in composite materials. A composite is a mixture of materials, often with a “matrix” and a “reinforcement” material. The matrix can be some type of plastic (also known as a polymer), or it can be ceramic or metal. This matrix is then strengthened and reinforced by the fiberglass (or glass fibers).

Many just call this “fiberglass” as well, because the matrix uses fiberglass reinforcement. But nowadays some use the term “glass-reinforced plastic” when the manufacturer uses plastic variations like vinyl, polyester or epoxy. This GRP differentiates it from FRP.

What’s FRP?

FRP stands for fiber-reinforced polymer. A polymer is a chemical compound with molecules designed like a long chain. A natural polymer includes rubber, but you have synthetic polymers too. Pliable synthetic polymers are called thermoplastics while the permanently rigid ones are called thermosets.

The polymer matrix is then reinforced with fiber. The key difference here is that the fibers used can be glass (fiberglass) or it can be made from other materials. The manufacturer may instead use fibers of carbon, or aramid, or even natural materials like cellulose. Even graphite and boron can be used as fibers too.

Conclusion

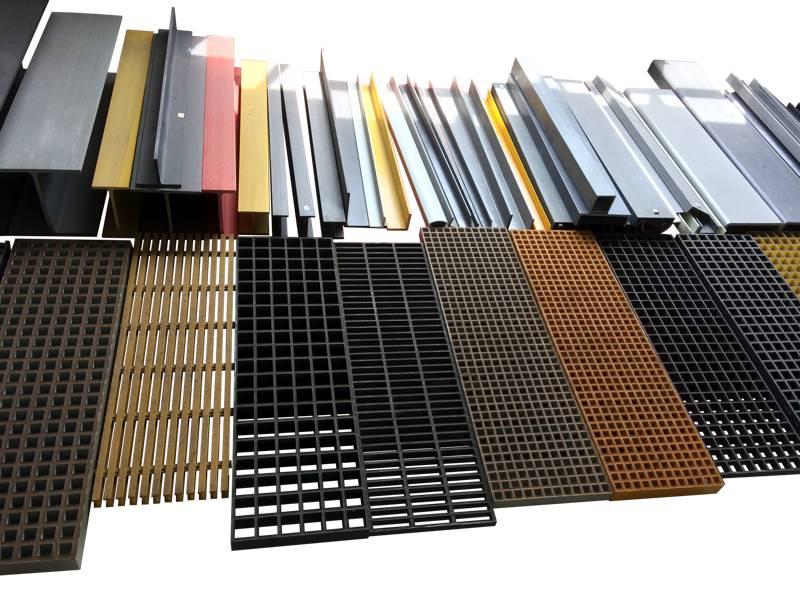

FRPs are used more and more in construction and manufacturing because it’s generally quite strong even while it’s lightweight. In many cases, it can be 7 times stronger than steel and even twice as strong as aluminum, which is already famous for being strong for its weight. FRPs and fiberglass are even stronger.

Since manufacturers have a choice in the materials you use for the matrix and for the reinforcement, you can have many types of FRPs. Many manufacturers come with their own formulas so that their FRP can have special characteristics. They can have exceptional strength and resistance to vibration and impact. They can also be extremely resistant to heat and chemicals. It all depends on the particular formula used.

But technically, fiberglass and FRPs aren’t the same. The FRP doesn’t have to use fiberglass at all, since it can use carbon or cellulose fibers instead.

So how do we make this clear? One analogy to use is the case of dogs and canines. You can use the term

“canines” for dogs, because that’s what they are. But other canines include wolves, foxes, and coyotes. You may call these animals “dogs” as well, but technically they are very different from domesticated dogs. Dogs are canines, but not all canines are dogs.

The same goes for fiberglass. Fiberglass or glass-reinforced polymers is a type of FRP. But not all FRPs are fiberglass, because not all of them use fiberglass as reinforcement. GRPs are FRPs, but not all FRPs are fiberglass.